Known for its excellent machinability and formability, 1018 steel—often classified as low-carbon or mild steel—is a popular choice in steel CNC machining. It offers great performance in forging, welding, and bending, making it ideal for components that demand precise shaping or repeated forming. This steel grade is frequently used for manufacturing pins, shafts, spindles, and rods. Additionally, 1018 is compatible with surface hardening treatments like carburizing, which enhances its wear resistance without affecting core ductility.

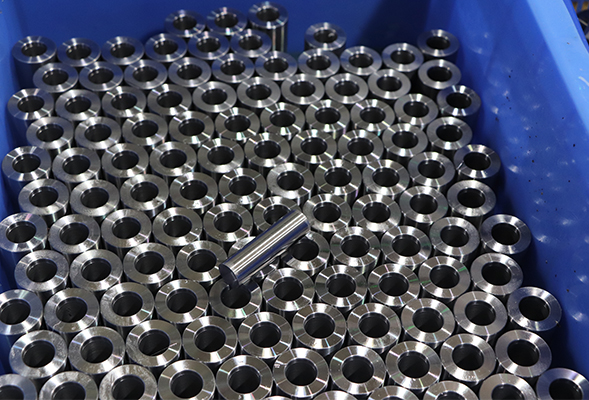

Steel CNC machining frequently uses carbon steel, alloy steel, and tool steel. Popular grades include 1018 (easy to machine), 1045 (higher strength), and 4140 (high toughness and wear resistance). Each type offers different mechanical properties for various industrial applications.