Introduction

Aluminum CNC machining is one of the most widely used manufacturing processes in modern industries. Thanks to its excellent machinability, lightweight properties, and cost efficiency, aluminum is often the first choice for CNC machined parts.

In this guide, we explain:

Why aluminum is ideal for CNC machining

Common aluminum grades for CNC machining

CNC machining cost for aluminum parts

Typical applications across industries

This article helps engineers and buyers choose the right aluminum material while optimizing CNC machining cost.

Why Aluminum Is Ideal for CNC Machining

Aluminum offers a unique balance of performance and cost in CNC machining manufacturing.

Key Advantages of Aluminum CNC Machining

Excellent machinability (faster cutting speeds)

Lightweight but strong

Corrosion resistance

Good thermal and electrical conductivity

Lower CNC machining price compared to steel

Because of these advantages, aluminum CNC machining is widely used in both prototype and production machining services.

Common Aluminum Grades for CNC Machining

Different aluminum grades affect CNC machining cost, strength, and performance.

1. Aluminum 6061 – Most Popular Choice

Excellent machinability

Good strength-to-weight ratio

Widely available in China CNC machining shops

Cost-effective for CNC machining services

Best for:

CNC machine parts, automotive CNC machining, industrial components

2. Aluminum 7075 – High Strength

Best for:

CNC motorsport, aerospace, high-load custom machined parts

3. Aluminum 5052 – Corrosion Resistant

Best for:

Marine components, enclosures, custom CNC parts

4. Aluminum 2024 – Aerospace Grade

Best for:

Aerospace and high-performance applications

Aluminum CNC Machining Cost: What to Expect

Aluminum CNC machining is generally more affordable than steel CNC machining or stainless steel CNC machining.

Typical Aluminum CNC Machining Cost Factors

Because aluminum cuts faster and causes less tool wear, it significantly reduces CNC machining cost per hour.

Aluminum CNC Machining vs Steel CNC Machining

| Factor | Aluminum CNC Machining | Steel CNC Machining |

|---|

| Machinability | Excellent | Moderate |

| Weight | Light | Heavy |

| CNC Machining Cost | Lower | Higher |

| Tool Wear | Low | High |

| Typical Use | Lightweight parts | Structural parts |

For cost-sensitive projects, aluminum CNC machining is often the better option.

CNC Machining Processes for Aluminum Parts

CNC Milling Machining

Best for complex geometries

Widely used for CNC milling parts

Supports 3 axis, 4 axis, and 5 axis CNC machining

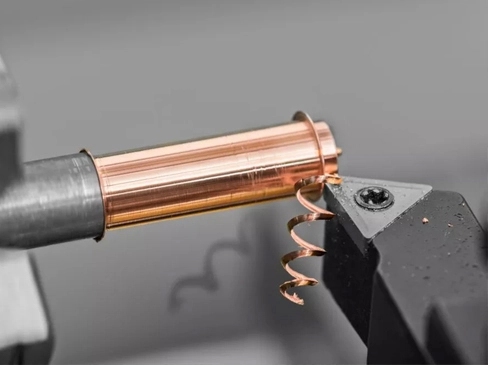

CNC Turning

Ideal for round aluminum parts

Lower CNC machining price

High efficiency for turning parts

5 Axis CNC Machining

Choosing the right process helps optimize total CNC machining cost.

Surface Finishing Options for Aluminum CNC Parts

Aluminum supports a wide range of finishes:

Surface finishing affects both appearance and CNC machining price.

Applications of Aluminum CNC Machining

Automotive CNC Machining

Custom auto parts

Engine brackets

Structural components

CNC Motorsport and Racing

Electronics and Industrial Equipment

Heat sinks

Enclosures

CNC machine parts

Aerospace and Robotics

How to Reduce Aluminum CNC Machining Cost

Use standard aluminum grades (6061)

Avoid unnecessary tight tolerances

Design parts for 3 axis CNC machining when possible

Increase order quantity

Work with experienced CNC machining manufacturers

These steps ensure cost-effective aluminum CNC machining without compromising quality.

FAQ: Aluminum CNC Machining

What is the best aluminum for CNC machining?

Aluminum 6061 is the most commonly used due to its machinability and cost efficiency.

Is aluminum CNC machining cheaper than steel?

Yes. Aluminum CNC machining typically has a lower CNC machining cost.

Can aluminum be used for high-strength applications?

Yes. Aluminum 7075 is suitable for high-strength CNC machined parts.

Is aluminum CNC machining widely available in China?

Yes. China CNC machining manufacturers offer a full range of aluminum CNC machining services.

Conclusion

Aluminum CNC machining offers an ideal balance of performance, precision, and cost. By choosing the right aluminum grade, machining process, and CNC machining service provider, buyers can achieve high-quality parts while keeping CNC machining price under control.