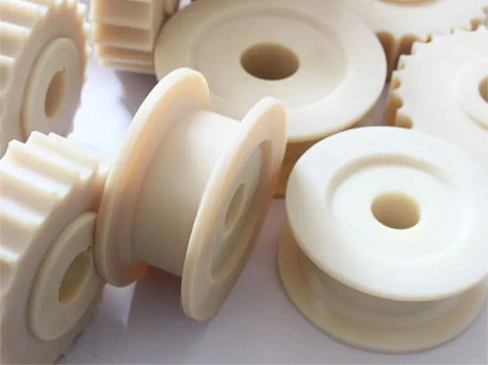

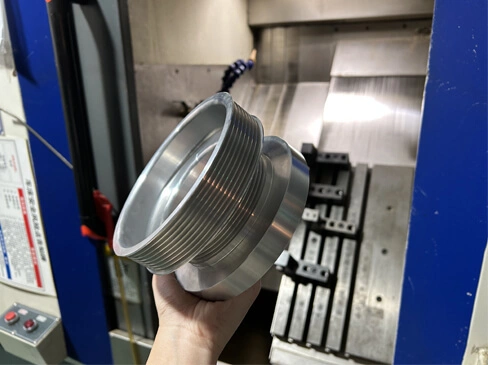

CNC machining is a technology that uses computer programs to control machine tools (such as lathes and milling machines) to perform precision machining on workpieces. It enables high-precision, automated cutting, drilling, and forming operations and is widely used in the manufacture of parts made of metals, plastics and other materials.

Anodizing is a chemical or electrochemical treatment performed on the surface of metals, especially aluminum, to form a dense oxide film to enhance corrosion resistance, wear resistance, insulation, or decorative properties.

Oxidation Surface Treatment Methods Commonly Used in CNC Machining

Anodizing: A metal workpiece is placed in an electrolytic cell as the anode. Direct current is passed through an acidic solution such as sulfuric acid or chromic acid. Electrolysis forms an oxide film on the metal surface. This film is tightly bonded to the substrate, with an in-layer growth of up to 50–55%. It exhibits a porous structure, high hardness, corrosion resistance, and wear resistance, and can be dyed to produce a variety of colors. The aluminum oxide layer formed on the surface of anodized aluminum alloy parts is harder, significantly enhancing corrosion and wear resistance. Furthermore, this porous oxide film can absorb dyes, giving the metal surface a rich decorative color.

Chemical oxidation: A thin oxide film (such as black oxide) is formed on the metal surface using acidic or alkaline chemical solutions. The film is generally thin and the formation process is relatively simple, but it primarily serves rust prevention and decorative purposes.

Anodizing is a very common surface treatment for CNC parts. It not only forms a strong protective layer for its function but also allows a single metal surface to display a variety of decorative colors. Colored anodized metal parts have a unique appeal in racing, motorcycle, bicycle, and other custom applications. The oxidized metal surface is virtually impermeable, significantly increasing its hardness while also slowing chemical corrosion, significantly extending the life of the part. In short, the combination of China CNC machining service and anodizing provides comprehensive quality improvements for parts, from structure to surface.

MQJM's Professional Strength in CNC Machining & Surface Finishing

MQJM has over 20 years of experience in precision CNC services. We possess extensive expertise in high-precision, complex CNC machining and subsequent surface treatment, providing customers with one-stop services from part processing to surface treatment.

MQJM maintains a rigorous quality control process: all machined parts undergo precise inspection to ensure that the dimensions and surface finish meet design requirements. We can flexibly customize surface colors and textures to meet customer needs, from elegant black to metallic to vibrant decorative colors. With over 20 years of professional experience and a rich portfolio of case studies, MQJM truly utilizes technology to meet customers' diverse needs for precision, performance and appearance.

Contact us today—and let's make your parts exceptional.