In the field of precision CNC machining, stainless steel has become one of the most widely used materials for producing high-quality parts. However, even stainless steel is not completely immune to corrosion. This is where stainless steel passivation plays a vital role. At MQJM, we specialize in CNC machining of stainless steel components and apply advanced passivation processes to ensure the durability, appearance, and reliability of every part we deliver.

What is Stainless Steel Passivation?

Passivation is a chemical process that removes free iron and other contaminants from the stainless steel surface, creating a thin and invisible oxide layer. This protective film significantly improves the material’s resistance to corrosion, extending the lifespan of the parts. Unlike coatings or plating, passivation enhances the inherent properties of stainless steel without altering its dimensions, making it especially suitable for precision CNC machining parts.

Why is Passivation Needed?

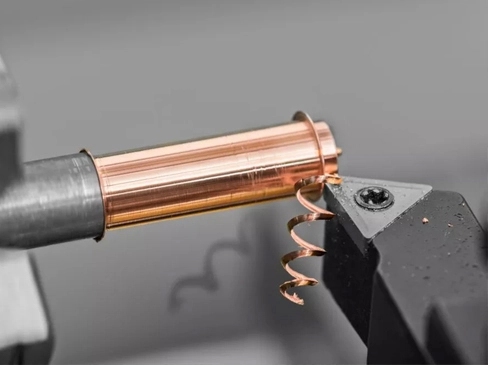

During CNC machining, stainless steel surfaces can be exposed to contaminants such as iron particles or cutting fluids. If not treated properly, these contaminants may lead to rust spots or premature corrosion. Passivation eliminates these risks by restoring the chromium-rich oxide layer that naturally protects stainless steel. This ensures the surface remains smooth, clean, and resistant to harsh environments.

The Benefits of Passivation

① Enhanced Corrosion Resistance: A longer service life for CNC milling stainless steel parts.

② Improved Surface Quality: Smooth, clean, and professional finish that meets customer requirements.

③ Reliability in Harsh Environments: Suitable for industries such as medical devices, aerospace, and automotive.

MQJM's Expertise in CNC Machining and Surface Protection

At MQJM, we combine advanced CNC machining capabilities with professional finishing techniques. From multi-axis machining of complex stainless steel parts to precision inspection and passivation, every step is designed to meet customer requirements. We focus not only on machining accuracy but also on protecting the surface of every component we deliver.

Our customers from industries such as medical equipment, electronics, and custom machinery value our attention to detail. With stainless steel passivation, we help them reduce maintenance costs, avoid premature failures, and gain confidence in the durability of their products.

Why Choose MQJM?

① Over a decade of CNC machining experience.

② Expertise in machining stainless steel, aluminum, and other metals.

③ Comprehensive solutions: from machining to assembly and surface treatment.

④ Commitment to quality and on-time delivery.

Conclusion

Stainless steel passivation is more than just a finishing process—it’s a guarantee of quality and long-term performance. At MQJM, we integrate this treatment with precision CNC machining to ensure that every stainless steel part we deliver has both accuracy and lasting protection.

Our mission is simple: protect every surface, ensure every detail, and deliver every part on time. If you are looking for a reliable CNC machining partner who understands the importance of surface protection, MQJM is one of reliable custom CNC precision machining suppliers.