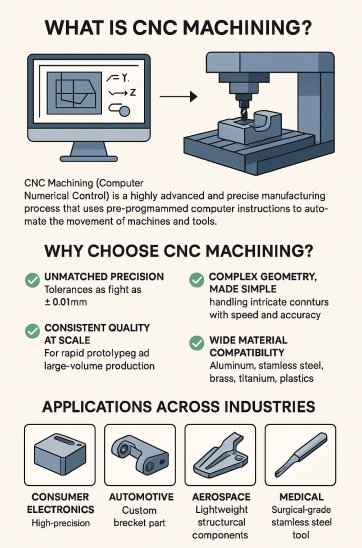

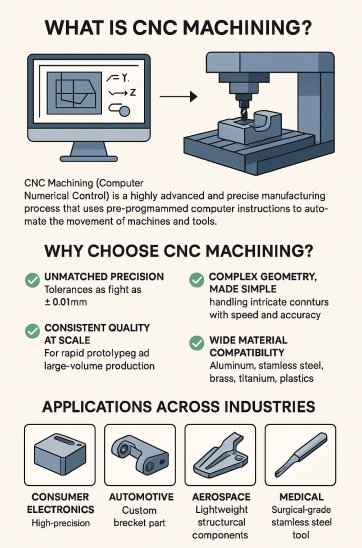

CNC machining (Computer Numerical Control) is a computer-driven manufacturing process where tools like mills and lathes automatically carve parts out of raw materials. Computers control the machine’s movements to cut, drill,mill, and shape materials (metals, plastics, composites, etc.) with high precision. In simple terms, the machine removes material from a solid block (the “workpiece”) under computer control, creating custom parts faster and more accurately than manual methods. This automated approach minimizes errors and waste, ensuring each part meets high precision.

Advanced CNC Equipment and Facilities

MQJM operates a modern, high-capacity workshop,the company currently maintains over 40+ CNC machines running 24/7, including numerous multi-axis units. In particular, MQJM’s facility has about 10 five-axis machining centers. Five-axis machines can move cutting tools along X, Y, Z axes and rotate around two additional axes, enabling one-shot machining of very complex shapes. This large fleet of machines – a mix of 3-axis, 4-axis and 5-axis mills and lathes – allows MQJM to handle multiple jobs in parallel for fast throughput.

Quality control is built in: MQJM employs a professional QC team and precision measurement equipment to inspect every part. All machines are calibrated and parts are checked against designs, ensuring parts meet specifications. This combination of state-of-the-art equipment and rigorous inspection means MQJM can produce high-quality parts efficiently.

Materials and Machining Processes

MQJM can machine a wide variety of materials. Its inventory includes 40–50+ certified materials, such as aluminum alloys, stainless steels, brass, copper, titanium, plus engineering plastics and composite materials. In practice, MQJM regularly produces parts from metals and plastics alike – from simple steel brackets to exotic composites – tailored to each customer’s needs.

The shop offers all standard CNC processes, for example:

Milling: Cutting and shaping flat or contoured surfaces with rotating tools.

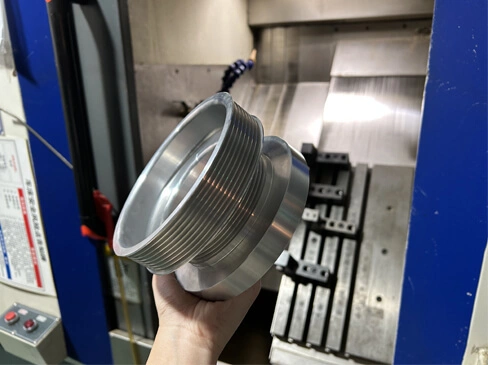

Turning: Producing cylindrical parts (shafts, bushings) by rotating the workpiece on a lathe.

Drilling & Boring: Creating or enlarging holes. MQJM performs drilling, reaming, tapping (thread-cutting), and boring operations to tight tolerances.

Thread Cutting & Tapping: Cutting internal or external threads on parts using CNC lathes or mills.

Other Operations: Chamfering, slotting, counterboring, and other secondary processes as needed.

With its diverse tool library and fixtures, MQJM can do everything from simple hole-making to complex multi-step machining sequences. Customers benefit from a one-stop service: CAD/CAM programming, machining, and finishing all under one roof, using processes chosen to maximize quality and efficiency.

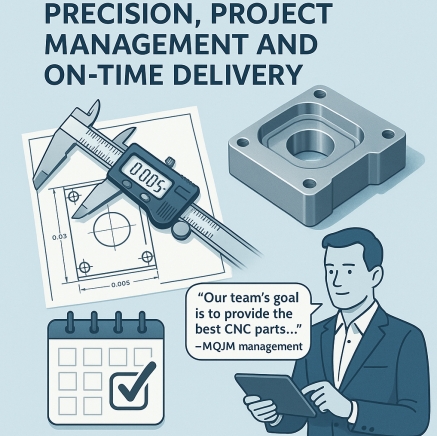

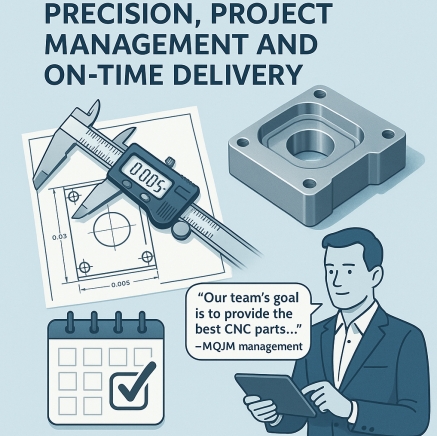

Precision, Project Management and On-Time Delivery

MQJM is built for precision and reliability. The plant follows ISO-9001 standards and strict tolerances – down to ±0.005 mm for critical dimensions. In practice, this means most machined parts leave the factory accurate within a few microns, meeting exact drawings. Such precision is vital for industries like aerospace and medical devices, where even tiny deviations are unacceptable.

To control delivery times, MQJM uses professional project management and scheduling. With 40+ machines and continuous (24/7) operation, the factory can produce parts very quickly. In fact, regular CNC parts can often be manufactured and shipped in about 10 days. Prototype samples can sometimes be ready in one week. Customers note that MQJM consistently meets deadlines. By combining efficient workflows and real-time tracking, MQJM ensures on-time delivery without sacrificing quality.

“Our team’s goal is to provide the best CNC parts… always prioritizing the customer. We actively offer solutions to ensure customer satisfaction” – MQJM management.

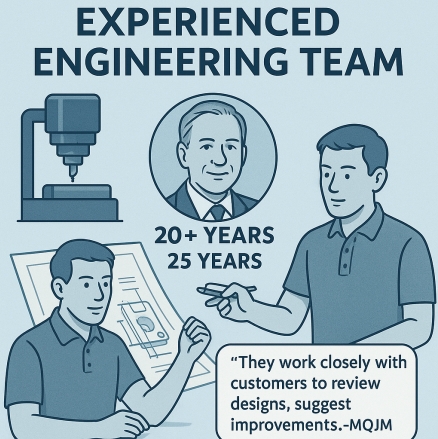

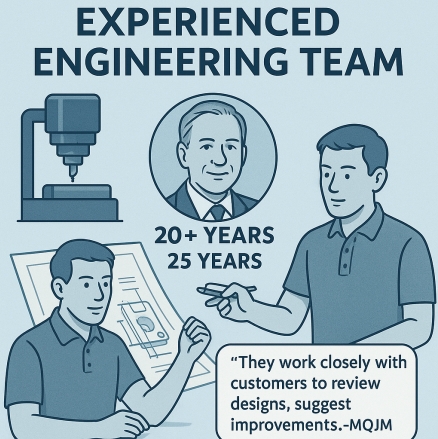

Experienced Engineering Team

Behind the machines is a highly skilled team. MQJM itself has over 20 years of experience in precision machining, and its engineers are veteran professionals. Many design and process engineers have decades of machining experience (the CEO alone has 25 years in precision parts production). Overall, the core CNC engineering team averages well over 15 years of experience each. This deep bench of know-how means complex projects are handled expertly: engineers can optimize cutting strategies, select the right tools and fixtures, and troubleshoot issues quickly.

In short, MQJM’s staff combines advanced training with practical expertise. They work closely with customers to review designs, suggest improvements (for manufacturability and cost), and manage each order from quote to final delivery. The result is a service where projects proceed smoothly even when parts have tight tolerances or intricate geometries.

Multi-Industry Capability and Complex Projects

MQJM serves a broad range of industries thanks to its versatile capabilities. From automotive and custom CNC motorcycle parts to precision racing parts, aerospace, medical devices, and electronics, MQJM can produce the necessary parts for each field. For example, they routinely machine:

Automotive/Motorcycle: Brackets, engine components, drivetrain parts (metal or plastic) with lightweight, durable designs.

Racing: High-performance bicycle and racecar parts (aluminum, carbon-infused, etc.) requiring tight specs.

Aerospace: Aircraft structural or engine parts (e.g. ribs, impellers) made from high-grade aluminum or titanium.

Medical Devices: Precision surgical or diagnostic tool components from stainless steel or medical-grade alloys.

Electronics: Housings and connectors for electrical equipment.

......

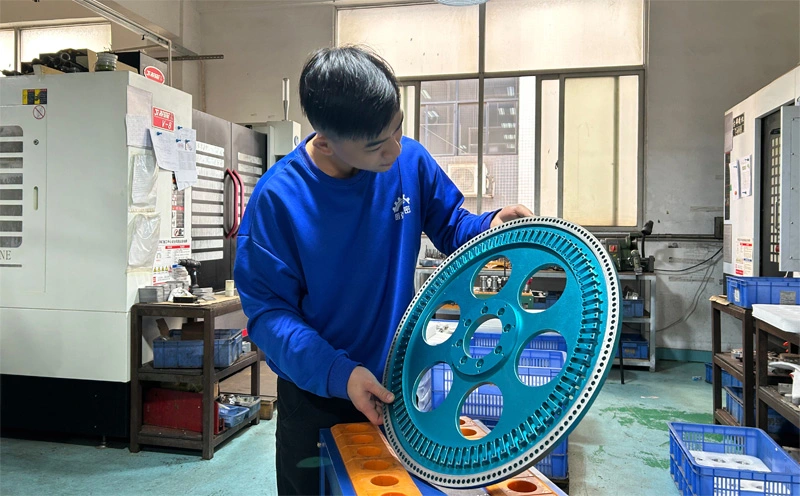

MQJM’s five-axis machining excels at freeform shapes: it can create entire impeller wheels, turbine blades, or curved molds in one set-up. The image above shows a high-precision impeller produced by MQJM. Parts like this – with complex curves and tight tolerances – are made routinely. Across all industries, MQJM blends cutting-edge machines and craftsmanship to deliver parts that meet each sector’s standards.

MQJM: A Reliable CNC Partner

In summary, MQJM stands out as a reliable, efficient, and trustworthy high precision CNC machining services partner. The company combines world-class equipment, strict quality control, and deep expertise to provide “precise, reliable, and efficient” production. Every stage (material selection, machining, inspection) follows international standards, backed by continuous communication with the customer. Reviews highlight that MQJM is “professional, reliable, and efficient,” making complex parts stress-free for clients.

For international procurement, MQJM offers the advantage of fast quotes, flexible volume (from prototypes to large batches), and global shipping experience. In practice, MQJM’s strength is delivering high-quality parts on time, every time. With transparent project tracking and dedicated support, you can always count on MQJM as a long term partner for CNC precision parts.