What Are CNC Fasteners?

CNC fasteners are precision connectors manufactured through Computer Numerical Control (CNC) machining, typically including bolts, studs, screws, and nuts. Compared with traditional fasteners, CNC machining utilizes advanced programming and control technology to achieve exceptional precision and consistency. This high-accuracy manufacturing ensures that every component fully complies with design specifications, preventing assembly mismatches or thread damage.

As a result, CNC fasteners are widely used in industries such as automotive, aerospace, electronics, and construction structures, playing critical roles in fixing and load-bearing applications. As highlighted by industry leaders like Stanley Engineering Fasteners, precision CNC machining enables the production of parts that meet high strength, superior quality, and strict tolerance requirements, significantly enhancing overall assembly reliability.

Manufacturing Process of CNC Fasteners

The production of CNC fasteners generally includes several key stages:

Design – Creating 3D drawings and defining dimensional parameters based on customer requirements.

CNC Programming – Writing machining programs and uploading them to the CNC machine.

Machine Setup – Selecting appropriate tools and preparing equipment.

Precision Machining – CNC machines cut and shape raw materials into bolts, screws, and other fastener components.

Throughout this process, machining operations are governed by precise programming, ensuring that the shape, dimensions, and tolerances of every part remain consistent. For example, custom CNC precision machining can achieve tolerances as tight as ±0.0001 inches (≈0.0025 mm), enabling every fastener to replicate the original design with accuracy. This level of precision effectively eliminates dimensional deviations and quality problems caused by vibration or human error, thereby improving the reliability and consistency of fasteners.

MQJM's Advantages in CNC Fastener Manufacturing

As one of professional custom CNC precision machining suppliers, MQJM stands out with superior equipment, advanced technology, and strict quality management, meeting customer demands for both high precision and reliability.

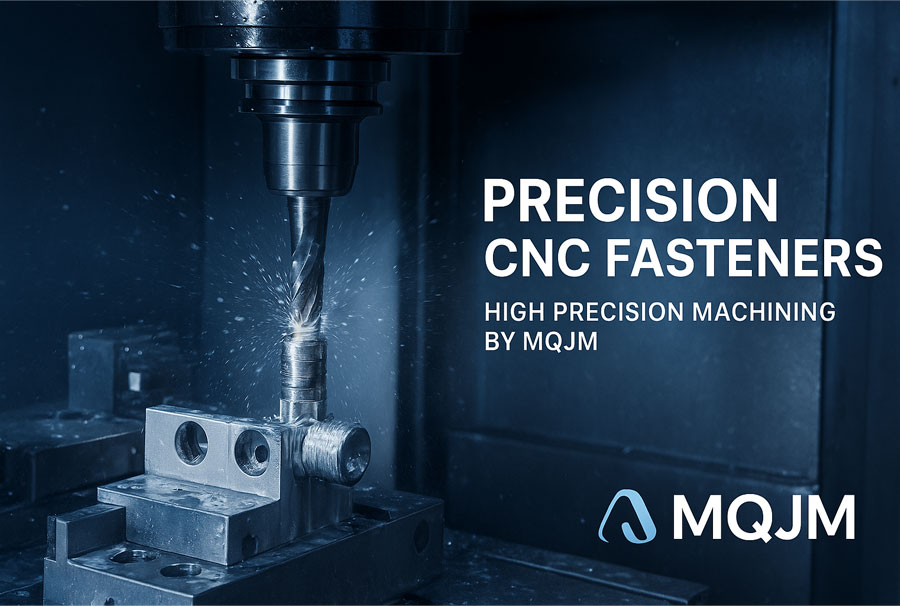

1. High-Precision Machining

MQJM operates advanced CNC machines with repeatability up to 0.005 mm, ensuring all fasteners fall within the specified tolerance range. This guarantees reliable connections and reduces the risks associated with dimensional variation.

2. Multi-Axis Machining Capabilities

Equipped with 4-axis and 5-axis CNC machining centers, MQJM can complete complex geometries and multi-surface machining in a single setup. Multi-axis machining enables cutting tools to work from multiple angles without repeated repositioning, significantly improving efficiency, surface finish, and overall stability.

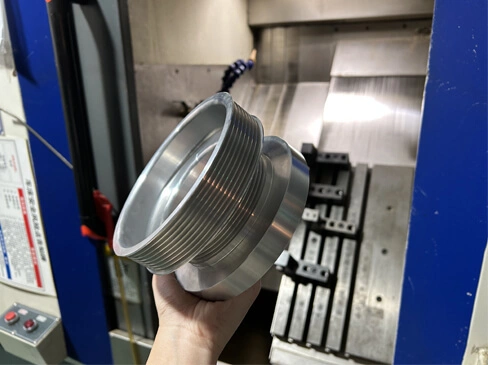

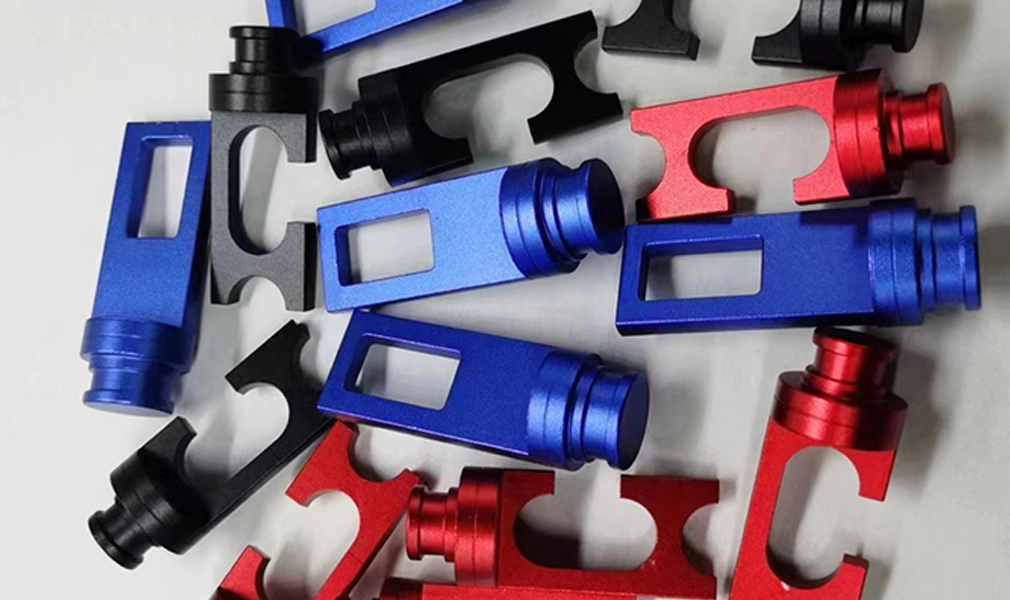

3. Wide Material Coverage

MQJM supports CNC machining for a broad range of materials, including:

Metals: Aluminum alloys, brass, copper, stainless steel, alloy steels

Plastics: POM (Delrin), ABS, Nylon, and other engineering-grade polymers

From lightweight, corrosion-resistant aluminum fasteners to high-strength, wear-resistant steel bolts, MQJM provides tailored solutions. Advanced plastics such as ABS, Nylon, and POM offer excellent chemical and dimensional stability, making them ideal for electrical housings and structural supports. For components requiring superior strength, stainless steel and alloy steels can be further enhanced with heat treatment and surface finishing to withstand demanding environments.

4. Professional Engineering and Quality Control

MQJM employs an experienced engineering team and strictly follows the ISO 9001 quality management system. A comprehensive quality control process is implemented at every stage—from raw material inspection and in-process monitoring to final product testing. This ensures stable and consistent quality, reduces defects and rework, and guarantees that customers receive high-performance CNC fasteners that meet international standards.

Conclusion

In summary, MQJM leverages its strengths in high-precision machining, multi-axis capabilities, versatile material processing, and ISO-certified quality systems to deliver customized CNC fastener solutions of superior quality.

Whether you need prototype samples, small-batch production, or large-scale manufacturing, MQJM has the technical expertise and strict management processes to meet the high-performance demands of multiple industries.

By choosing MQJM, customers gain access to CNC fasteners that not only meet strict specifications but also offer long-lasting durability and exceptional reliability.