Background

On November 28, 2024, MQJM received an inquiry from a customer specializing in the design of electric bicycle components. Although the client had a stable supplier, the original partner could no longer meet increasingly tight delivery schedules due to the expansion of their business. Founded in 2011, MQJM focuses on high-precision machining and manufacturing of metal and plastic parts. With extensive industry experience and advanced CNC equipment, MQJM has become the ideal alternative supplier thanks to its dedication to quality machining and customer-first philosophy.

Cooperation Opportunity

The customer discovered MQJM’s website through Google and submitted an inquiry with attached design drawings. Upon receiving the inquiry, MQJM immediately conducted an internal evaluation and quickly provided a competitive quote tailored to the customer’s requirements. The two parties communicated via email and phone, discussing machining processes, materials, precision standards, and delivery timelines in detail. Through efficient technical and business exchanges, a mutual understanding was reached, and the cooperation was quickly confirmed. The smooth communication and strong business alignment laid the groundwork for a successful partnership.

Solution & Results

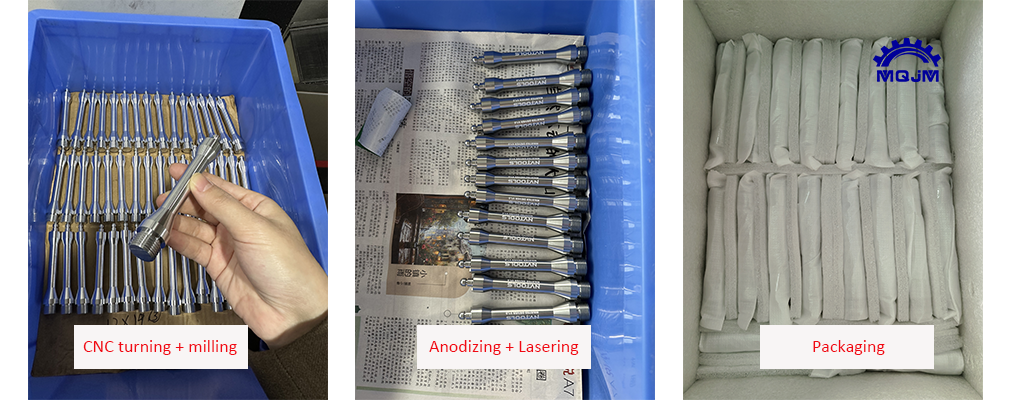

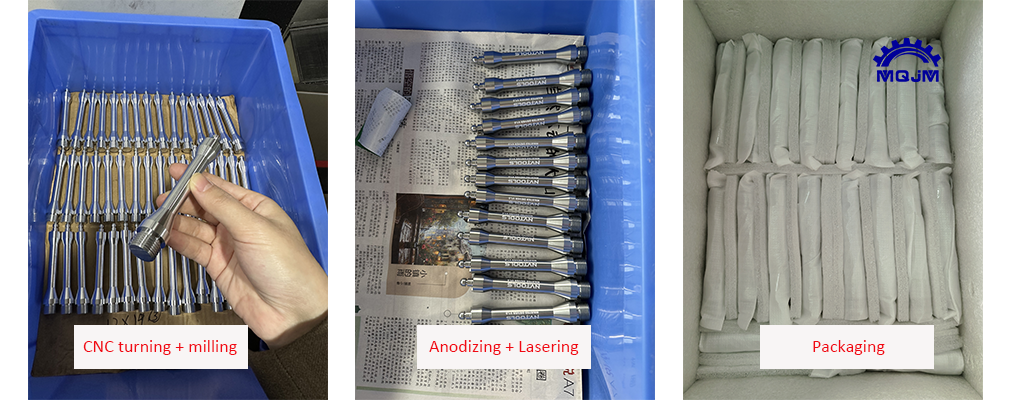

Leveraging its professional production capabilities and flexible, efficient management system, MQJM delivered high-quality components at the initial stage of cooperation. The customer was highly satisfied with the quality, pricing, and lead times, and subsequently submitted multiple new projects for quotation. MQJM responded promptly and confirmed sample production to test the new parts. This phase coincided with the pre-Chinese New Year production rush, but MQJM utilized its equipment and team coordination strengths to complete and ship the samples within just one week. The customer praised the dimensional accuracy and surface finish, and soon entrusted MQJM with CNC machining for a broader range of metal components. This project demonstrated MQJM’s strong capabilities and reliability in parts manufacturing, forming a solid foundation for long-term collaboration.

Client Feedback & Deeper Collaboration

During production, the customer visited MQJM’s facility in person. The MQJM team warmly welcomed them and guided them through the workshops and quality inspection labs. In on-site discussions, the two sides deeply explored key technical requirements such as machining methods, tolerances, precision, and surface finishes. This face-to-face communication helped MQJM better understand the customer’s priorities and offer tailored solutions based on the characteristics of each component.

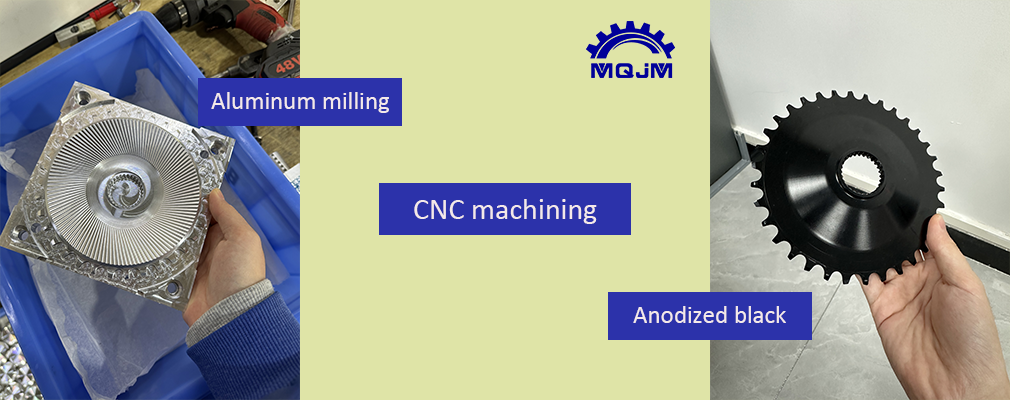

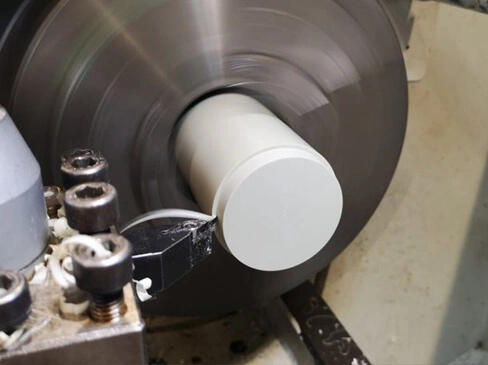

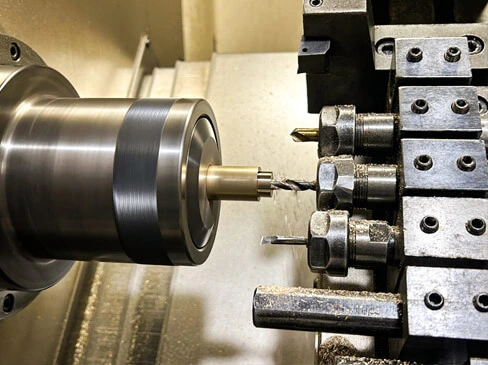

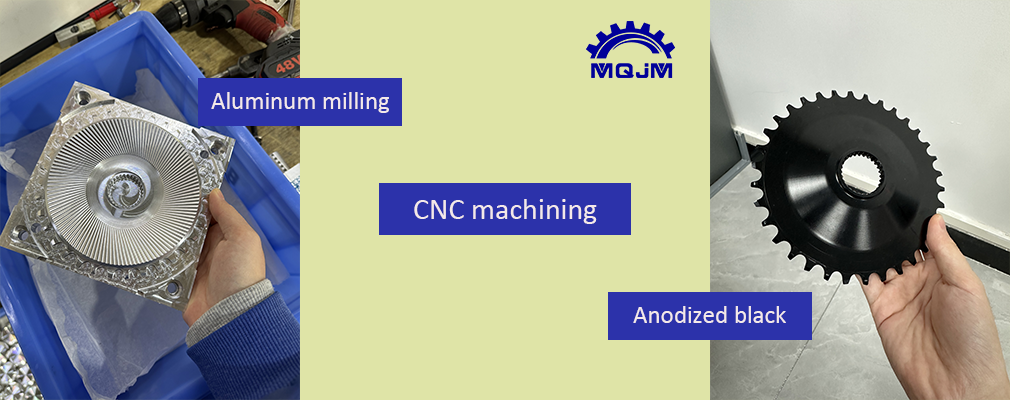

The customer expressed interest in using different machining processes for different products to reduce costs. MQJM’s engineers analyzed the design and functional aspects of each part and recommended optimal manufacturing strategies. For example, for parts suitable for batch machining, MQJM applied efficient CNC turning and milling. For components with large hollow sections, MQJM suggested extrusion followed by CNC milling — ensuring high precision while reducing costs.

The customer appreciated MQJM’s proactive technical input, recognizing the company’s ability not only to deliver high-quality parts but also to significantly enhance cost-efficiency. The customer expressed full satisfaction with MQJM’s services and product quality and looked forward to a deeper, long-term partnership.

MQJM Advantages

Extensive Expertise: Founded in 2011, MQJM specializes in precision CNC machining of metal and plastic parts. With over 50 skilled employees and 60+ advanced machines, MQJM delivers stable and reliable production capacity.

High-Precision Machining: Equipped with strict quality control systems and advanced measurement instruments, MQJM can achieve tolerances as tight as ±0.005mm, meeting the highest standards for precision parts.

Diverse Materials & Finishes: MQJM offers more than 40 certified materials and over 10 surface treatment options (e.g., anodizing, plating, painting, heat treatment), enabling fully customized solutions.

Customer-Oriented Service: Committed to customer satisfaction, MQJM maintains close communication, provides proactive engineering suggestions, and helps customers reduce production costs while improving competitiveness. On-time delivery is a constant promise, even during peak seasons.

Win-Win Partnerships: This collaboration established a strong foundation of mutual trust. By optimizing both technology and cost, MQJM and the customer achieved a true win-win. Moving forward, MQJM will continue leveraging its strengths in machining and component manufacturing to grow together with its customers and explore broader markets.