Introduction

One of the most common questions engineers and buyers ask is:

“What is the cost of CNC machining?”

Whether you are sourcing CNC machining services for prototypes or mass production, understanding CNC machining cost helps you control budget, optimize design, and choose the right CNC machining manufacturer. In this guide, we explain CNC machining price factors, cost comparisons, and proven ways to reduce CNC machining cost without sacrificing quality.

What Is the Cost of CNC Machining?

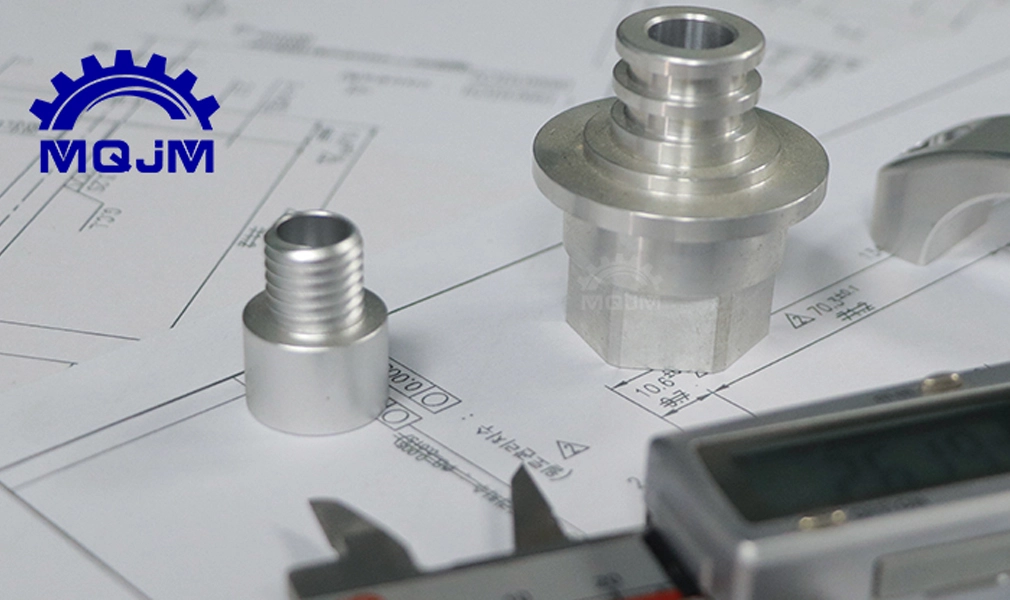

The cost of CNC machining refers to the total expense required to manufacture CNC machined parts using CNC milling, CNC turning, or multi-axis CNC machining processes.

Typical CNC machining price includes:

CNC machining cost varies significantly depending on part design, material, tolerance, and production volume.

CNC Machining Cost Per Hour (Typical Range)

Although prices vary by region and machine type, the average CNC machining cost per hour is:

| Machine Type | Typical Cost per Hour |

|---|

| 3 Axis CNC Machining | $30 – $60 |

| 4 Axis CNC Machining | $45 – $80 |

| 5 Axis CNC Machining | $70 – $150 |

| Swiss CNC Machining | $60 – $120 |

China CNC machining generally offers lower hourly rates compared to Europe and the United States due to labor efficiency and supply chain advantages.

Key Factors That Affect CNC Machining Price

1. Material Selection (Material CNC Cost)

Material choice is one of the biggest cost drivers in CNC machining manufacturing.

Common CNC machining materials and cost impact:

Choosing the right CNC materials can significantly reduce machining cost.

2. Part Design and Complexity

Complex designs increase CNC machining price due to:

Designs optimized for CNC machining reduce tool changes and machining time.

3. Tolerance and Precision Requirements

CNC precision machining with tight tolerances (±0.01 mm or tighter) requires:

Precision machining CNC always costs more than standard tolerance machining.

4. Machining Process Used

Different processes affect cost differently:

CNC milling machining: Suitable for complex shapes

CNC turning: Lower cost for round parts and turning parts

5 axis CNC machining: Higher cost but fewer setups

Swiss CNC machining: Ideal for small, high-precision parts

Selecting the right process minimizes total cost of CNC machining.

5. Production Quantity

CNC machining cost per part decreases as quantity increases:

Prototype and low-volume production: Higher unit price

Medium batch production: Balanced cost

High-volume production: Lower per-part cost

This is why CNC machining manufacturers often recommend batch optimization.

CNC Machining Cost: China vs Other Countries

CNC machining China remains one of the most cost-effective sourcing options.

| Region | Cost Level | Notes |

|---|

| China CNC Machining | Low | Mature supply chain, fast lead time |

| USA | High | Higher labor and overhead |

| Europe | High | Strict regulations |

| Southeast Asia | Medium | Limited precision capability |

Cheap CNC machining from China does not mean low quality when working with an experienced CNC machining shop.

How to Reduce CNC Machining Cost (Proven Methods)

1. Optimize Part Design for Machining

2. Choose Cost-Effective Materials

3. Select the Right Machining Process

4. Increase Order Quantity

Combining orders reduces setup and programming cost.

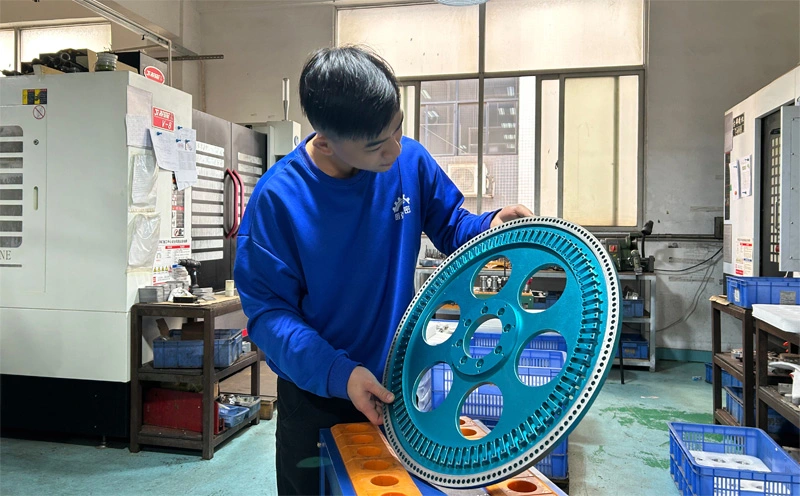

5. Work with the Right CNC Machining Manufacturer

An experienced machining manufacturer helps optimize design, material, and process before production.

Is Cheap CNC Machining Always a Good Choice?

Cheap CNC machining can be risky if it leads to:

Poor surface finish

Inconsistent tolerances

Delayed delivery

Quality issues

The goal is cost-effective CNC machining, not simply the lowest price.

CNC Machining for Sale: What Buyers Should Ask

Before placing an order, ask your CNC machining service provider:

What tolerance can you achieve?

What materials do you recommend?

How do you control quality?

Do you support custom machined parts?

Can you provide DFM feedback?

These questions help avoid hidden CNC machining costs.

FAQ: CNC Machining Cost

How much does CNC machining cost per part?

It depends on material, complexity, and quantity. Simple aluminum parts can start from a few dollars per piece.

Is CNC machining cheaper in China?

Yes. CNC machining China offers lower cost due to labor efficiency and supply chain advantages.

Why is 5 axis CNC machining more expensive?

5 axis CNC machining requires advanced machines, skilled operators, and higher programming cost.

What is the cheapest CNC machining material?

Aluminum and ABS machining are among the most cost-effective options.

Conclusion

Understanding the cost of CNC machining allows buyers to make smarter sourcing decisions. CNC machining price is influenced by material, design, precision, process, and volume. By optimizing these factors and choosing the right CNC machining service from CNC precision machining manufacturer, you can significantly reduce cost while maintaining quality.