Introduction

Many buyers search for cheap CNC machining hoping to reduce manufacturing cost. However, the lowest CNC machining price often comes with hidden risks such as poor quality, delays, or rework.

The real goal is not simply cheap CNC machining—but cost-effective CNC machining without risk.

In this guide, we explain how to reduce CNC machining cost safely, what affects CNC machining price, and how to choose a reliable CNC machining service while keeping quality under control.

What Does “Cheap CNC Machining” Really Mean?

Cheap CNC machining does not mean:

Poor tolerance

Low-grade materials

Unstable quality

No quality inspection

Instead, cheap CNC machining means:

When done correctly, low-cost China CNC machining can still meet professional engineering standards.

Key Factors That Drive CNC Machining Cost

Understanding CNC machining cost is the first step to reducing it.

1. Material CNC Cost

Material selection has a major impact on CNC machining price.

Switching from steel CNC machining to aluminum CNC or machining plastic can significantly reduce cost.

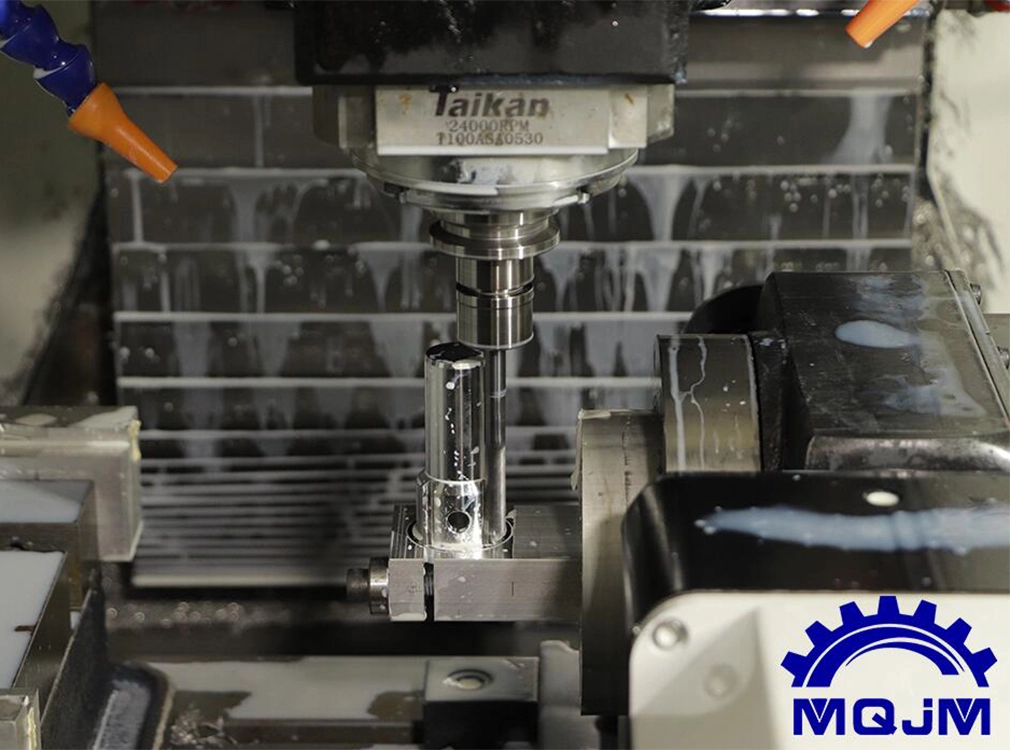

2. Machining Process Selection

Different CNC machining services have different cost structures:

Choosing the correct process avoids unnecessary cost.

3. Part Design and Complexity

Design features that increase CNC machining cost:

Tight tolerances (±0.01 mm or tighter)

Deep pockets and thin walls

Sharp internal corners

Complex 5 axis machining requirements

Design for manufacturability (DFM) is critical for cheap CNC machining.

4. Production Volume

Cheap CNC machining becomes more achievable with:

Batch production

Reduced setup repetition

Standard tooling

Low-volume prototypes always cost more per unit.

7 Proven Ways to Cut CNC Machining Cost Without Risk

1. Optimize Your Part Design for CNC Machining

These small changes reduce machining time significantly.

2. Choose Cost-Effective CNC Materials

Replace steel with aluminum CNC machining where possible

Use ABS machining or CNC polycarbonate for non-structural parts

Avoid exotic alloys unless necessary

Material CNC selection directly impacts machining cost.

3. Use CNC Turning Instead of Milling When Possible

Turning parts are generally cheaper than milled parts with similar geometry.

Lathe machining parts reduce CNC machining price and improve consistency.

4. Avoid 5 Axis CNC Machining Unless Required

5 axis CNC machining price is higher due to machine complexity and programming cost.

Use 3 axis or 4 axis CNC machining whenever possible.

5. Increase Order Quantity

Combining orders reduces:

This is one of the simplest ways to achieve cheap CNC machining.

6. Work With a CNC Machining Shop That Provides DFM Support

A professional CNC machining shop helps:

This prevents expensive mistakes before production.

7. Source from China CNC Machining Manufacturers

China CNC machining offers:

Cheap CNC machining in China is safe when working with experienced manufacturers.

Common Risks of Cheap CNC Machining (and How to Avoid Them)

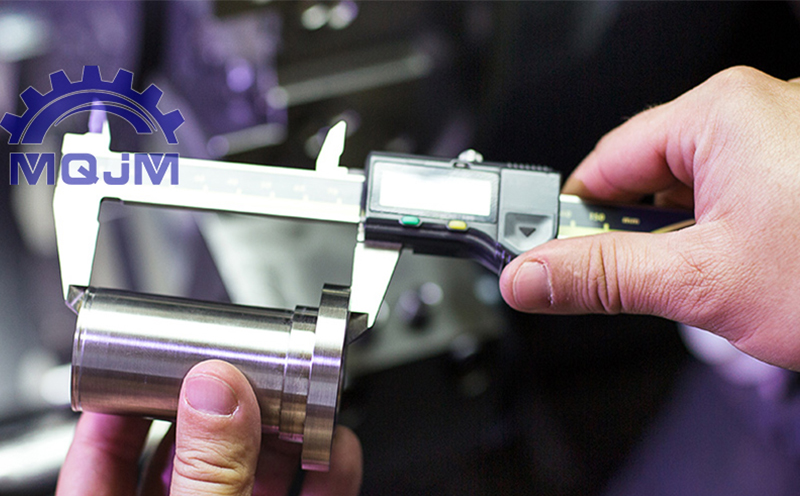

Risk 1: Poor Tolerance Control

Solution: Choose CNC machining manufacturers with in-house inspection.

Risk 2: Low-Quality Materials

Solution: Confirm material certificates and CNC materials specifications.

Risk 3: Unstable Quality

Solution: Ask about process control and inspection frequency.

Risk 4: Hidden Costs

Solution: Get a detailed CNC machining price breakdown.

Is Cheap CNC Machining from China Safe?

Yes—if you choose the right CNC machining service provider.

Reliable China CNC machining shops offer:

The key is supplier qualification, not just price comparison.

When Cheap CNC Machining Is NOT Recommended

Avoid low-cost CNC machining if:

Parts require ultra-tight tolerances

Safety-critical applications are involved

Regulatory compliance is strict

In these cases, prioritize quality over CNC machining price.

FAQ: Cheap CNC Machining

Is cheap CNC machining low quality?

Not necessarily. Cost-effective CNC machining focuses on efficiency, not quality sacrifice.

What is the cheapest CNC machining material?

Aluminum and ABS machining are usually the most affordable.

Does China CNC machining reduce cost?

Yes. China CNC machining offers lower CNC machining cost with competitive quality.

Why is 5 axis CNC machining expensive?

Advanced machines, skilled programming, and longer setup time increase cost.

Conclusion

Cheap CNC machining is achievable without risk when cost reduction is driven by smart design, material selection, process optimization, and the right CNC machining manufacturer.

Instead of chasing the lowest CNC machining price, focus on total cost efficiency and long-term quality.