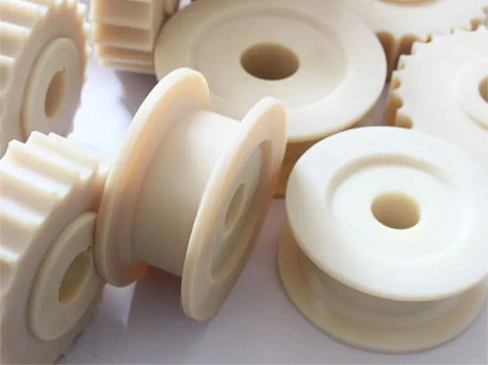

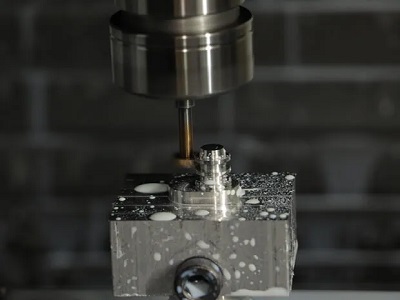

At MQJM, we specialize in CNC machining services, precision parts machining, and high-efficiency assembly to meet urgent customer demands without compromising quality. As our operations expand, we recently partnered with a new custom electric bicycle parts customer whose pre-orders exceeded expectations. Facing a manpower shortage, they urgently needed a manufacturing partner capable of fast CNC machining, reliable custom parts assembly, and on-time delivery.

They contacted MQJM immediately. After an initial discussion, we set a date for on-site CNC machining process review, assembly, and packaging training at our factory. This ensured every step — from parts machining to final assembly — met exact specifications and was completed within the customer’s tight deadline.

Precise Training, Efficient Cooperation

On August 4th, the customer and their engineer arrived at MQJM’s factory as scheduled. We began with a structured assembly training session, ensuring every packaging and assembly staff member clearly understood the workflow.

In our spacious packaging workshop, the customer proactively brought auxiliary tools and effectively combined them with MQJM’s in-house resources. Together, we built a streamlined assembly line that maximized work efficiency. Our packaging and assembly lead trained team members for their dedicated roles, ensuring smooth cooperation and minimal downtime.

Strict Inspection, Quality Assurance

Once assembly was complete, we carried out rigorous inspections using ammeters to test each assembled product. When a few units showed no electrical response, we worked closely with the customer to review their design concept, identify the issue, and perform immediate repairs. Every unit passed customer’s CNC machining and assembly quality standards before shipment.

Warm Moments, Genuine Cooperation

Despite the urgency of the project, the process was filled with warm moments:

The customer loved MQJM’s work uniforms so much they wore one while joining the assembly line.

They learned the location of every tool in just one day, retrieving them faster than some MQJM staffs.

They even brought original formula milk powder from their home country for our founder’s newborn, remembering a small detail from their first visit.

Efficient Delivery, Beyond Expectations

With demand surging, the schedule was extremely tight. Leveraging our CNC machining expertise, parts processing efficiency, and custom assembly skills, MQJM completed the entire assembly project in just two days — achieving on-time delivery and exceeding customer expectations.

At MQJM, we go beyond manufacturing. We combine precision CNC machining, custom parts assembly, and strict quality control with a customer-first approach. Choosing MQJM means choosing a partner who always puts quality and customer satisfaction first!