Anodizing is a widely used surface treatment for aluminum, especially in industries like aerospace, automotive, and precision machining. However, when working with 7075 aluminum alloy, engineers often encounter a recurring issue: surface patterns, streaks, or color inconsistencies after anodizing.

This article explores the core reasons behind this phenomenon and offers practical solutions to help manufacturers achieve a more consistent and aesthetically pleasing finish.

1. What Causes Surface Patterns on 7075 Aluminum During Anodizing?

1.1 Uneven Element Distribution Within the Alloy

7075 is a high-strength aluminum alloy, primarily composed of zinc, magnesium, and copper. These alloying elements can be unevenly distributed throughout the material, especially near grain boundaries or in areas of elemental segregation.

During anodizing, such variations cause uneven electrochemical reactions, resulting in inconsistent oxide layer formation. This leads to visible surface defects like streaks, blotches, or color shading.

1.2 Imperfect Pre-Treatment

The pre-anodizing steps—degreasing, alkaline etching, and acid neutralization—are critical in preparing the surface. Any imbalance in these processes may cause non-uniform surface activation or residual corrosion marks, which become magnified during anodizing.

For example, over-etching can roughen the surface excessively, while insufficient rinsing may leave chemical residues that disrupt the anodizing reaction.

1.3 Instability During the Anodizing Process

Parameters such as current density, electrolyte temperature, and fluid circulation directly affect oxide layer uniformity. 7075 is particularly sensitive to fluctuations in these variables, which can cause inconsistent layer thickness and visual surface differences.

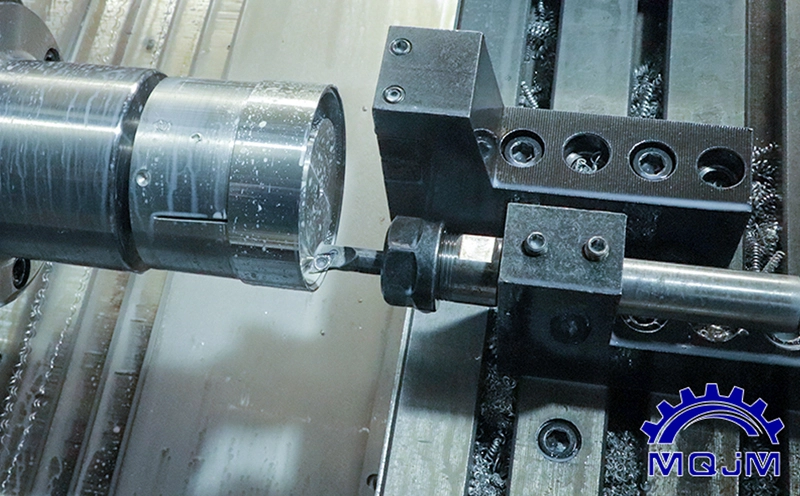

1.4 Residual Machining or Thermal Patterns

Parts made from 7075 aluminum machining are often CNC-machined or heat-treated. These processes may leave directional marks, stress lines, or grain structure variations that become more visible after anodizing.

2. How to Reduce or Eliminate Surface Patterns on 7075 During Anodizing

Although it’s difficult to eliminate surface texture completely, CNC service manufacturers can take several steps to greatly reduce its appearance through optimized materials and improved process control.

2.1 Choose High-Quality, Homogeneous Material

Select 7075 aluminum with refined grain structure and uniform composition, preferably aerospace-grade or homogenized billets. These reduce elemental segregation and ensure more consistent reactions during anodizing.

2.2 Optimize Pre-Treatment Processes

- Ensure thorough degreasing to remove all surface contaminants

- Carefully control etching duration to avoid uneven roughness

- Properly rinse and neutralize to maintain uniform surface activity

2.3 Maintain Stable Anodizing Conditions

- Use lower current densities and tightly controlled temperatures

- Implement fluid circulation systems for consistent electrolyte exposure

- Ensure complete contact using optimized racking to prevent uneven current flow

2.4 Consider Advanced Surface Treatments

For products requiring superior appearance and surface uniformity, advanced techniques can be applied:

- Micro-Arc Oxidation (MAO): Produces a thicker, more uniform oxide layer with excellent wear and corrosion resistance

- Plasma Anodizing: Offers consistent color and surface texture with minimal visible patterning

3. Conclusion

7075 aluminum is widely used for its exceptional mechanical properties, but its complex composition makes it prone to surface patterning during anodizing. These patterns arise from uneven element distribution, surface treatment inconsistencies, and unstable processing conditions.

By selecting high-quality materials and carefully controlling each stage of the anodizing process, manufacturers can significantly reduce visible surface defects and enhance product consistency and appearance.

If you're looking for customized anodizing solutions for CNC parts or custom CNC machined aluminum parts, feel free to contact our technical team—we’re here to help you achieve better results with confidence.

The Author

Name: Fan Zhang

"Expert in five-axis machining with a proven track record of mentoring over 100 apprentices. Many have become CNC engineers at leading companies and are now in high demand as technical consultants and trainers."